Ciptex®: Cryogenic Application

Endless possible in ultra-low temperature.

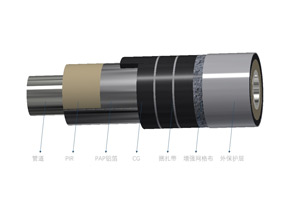

Polyisocyanurate foam is fabricated through the catalysis between isocyanate and polyether, it is one kind of the most used foam materials. Compared to other heat-resistant materials, the superiority on its low heat conductivity, low water absorption, high strength as well as its excellent inflaming retarding property make it the best choice for cryogenic pipe holder, saddle and low temperature block.

Herence has accumulated rich experience on material development and molding manufacture of PIR material components in cold insulation field. The company occupies advanced foaming and cutting machines and has attracted a great many chemical and mechanical experts.

The reliable third-party testing laboratory can guarantee excellent product quality. We can modulate our formula according to the request of our valued customer to satisfy the requirements of different design and construction.

Product Superiority

- Steady quality, uniform density;

- Thermosetting property, excellent antiflaming property;

- Low heat conductivity, superior thermal insulation;

- Wide temperature range: -196℃ ~+120℃;

- Outstanding physical property under normal and low temperature;

- Accurate dimension, outstanding durability;

- Differentiated customization.

Quality Management

Herence acquires ISO9001 Quality Management System Certification, and establishes quality management system involves the raw material purchase, the processing & production and the after-sale service which guarantees the quality of products and keep customer satisfied.

Application Case

CIPTEX 9340SP1 series products have passed the severe tests of GB/ASTM standard which satisfy the high request in the field of nuclear cold-insulation.